Manual inspection for defect detection is time-consuming, costly, and prone to human error, with operators often missing critical defects. This traditional approach not only slows down production but also increases costs and risks to product quality.

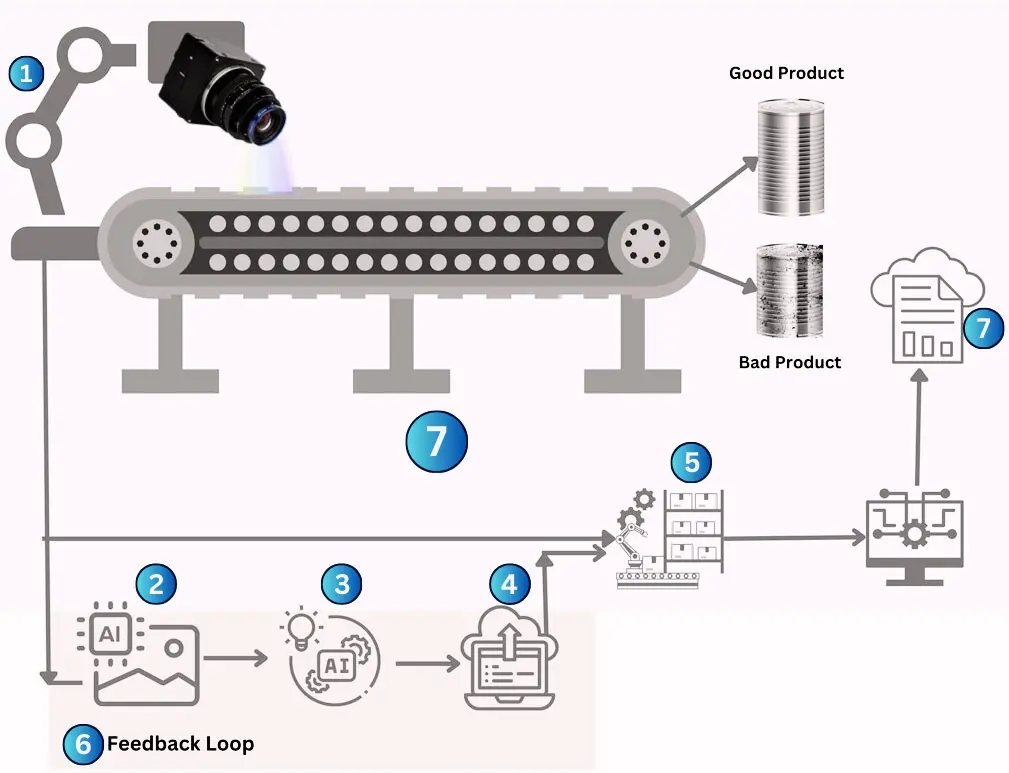

We automate the defect detection process with advanced machine vision systems and AI technology. Our solution seamlessly integrates into your manufacturing line, continuously monitoring and analyzing every product with precision and speed.

By leveraging cutting-edge AI algorithms and high-resolution imaging, we ensure that even the smallest defects are detected in real-time, eliminating the inefficiencies of manual inspection.

Cameras

CamerasChoosing the right camera and its associated components is crucial for effective defect detection and automating the visual inspection process. At Intelgic, we understand that every manufacturing environment is unique and products and materials vary, so we tailor our solutions to meet your specific needs.

We consider various factors such as defect size, working distance , product or material type, product size, inspection area, and the speed at which products move—whether on a conveyor belt or a roller. Based on these parameters, we provide the most suitable imaging solution, ensuring optimal performance for your inspection process. For more complex defects, we offer customized machine vision camera solutions designed to meet specialized requirements.

Illumination

IlluminationProper illumination is equally important for capturing clear and accurate images. We carefully select and position the lighting to highlight defects and ensure reliable detection.

Frame Grabber

Frame GrabberIn some cases, achieving high-resolution image capturing may require additional components, such as an external motherboard or frame grabber. We assess your needs and provide the right hardware to support your machine vision system, ensuring seamless integration and product quality inspection automation.

Machine Vision Cameras

Machine Vision CamerasIndustrial machine cameras are specialized imaging devices designed for rigorous inspection and quality control in manufacturing environments. These cameras offer a wide range of resolutions, typically ranging from 1 to 29 megapixels or higher, ensuring that even the smallest defects can be detected with precision. Industrial cameras are versatile in their output, providing a variety of formats such as raw, monochrome, and RGB, and can be equipped with different interfaces like GigE, USB, or Camera Link, depending on the speed and resolution requirements of the inspection process.

CIS cameras

CIS camerasContact Image Sensor (CIS) cameras are advanced imaging devices specifically designed for high-resolution scanning and microscopic defect detection on surfaces such as coatings, foils, fabrics, metal sheets, lithium battery coatings, printing materials, films, PCBs, apparel, LCD panels, and similar products. Unlike traditional cameras that rely on lenses, CIS cameras use a linear array of sensors positioned in direct contact with the object being scanned. This design allows them to capture highly detailed images with consistent illumination, ensuring uniformity and precision in inspection processes. CIS cameras deliver clear, distortion-free images, making them ideal for industries that demand the highest standards of accuracy and image quality.

Based on your product size, defect dimensions, and the speed of your conveyor belt, we can customize a CIS camera solution tailored to meet your specific requirements.

Line Scan camera and Area scan camera

Line Scan camera and Area scan cameraLine scan camera: Line scan cameras capture images one line at a time, making them ideal for inspecting fast-moving products on conveyor belts or continuous surfaces like textiles, paper, or metal sheets. They provide high-resolution images of long or cylindrical objects and are perfect for detecting linear defects.

Area scan cameras: Area scan cameras on the other hand, capture full-frame images in a single shot, making them suitable for inspecting stationary or slower-moving objects where precise, comprehensive coverage is needed.

Live Vision AI is a powerful software and AI algorithm specially designed for machine vision and visual inspection automation. It connects machine vision cameras with AI models and algorithms to automate inspection processes in manufacturing lines. With Live Vision AI, manufacturers can achieve real-time, accurate analysis of products, reducing the need for manual inspection and significantly improving production efficiency

Customized AI algorithms can easily be fed within the Live Vision to tailor the inspection process to specific industry needs, whether for detecting microscopic defects, ensuring product consistency, or optimizing overall quality control. Live Vision brings cutting-edge technology to modern manufacturing, driving precision and reliability in every inspection.

Intelgic's AI-powered Machine Vision and quality inspection automation system for defect detection across diverse manufacturing sectors. From electronics to pharmaceuticals, plastic products to flooring and printing materials, and even metal fabrication, this AI-driven system adapts seamlessly to diverse product types. Ensure exceptional quality control across your entire production line, regardless of what you make.

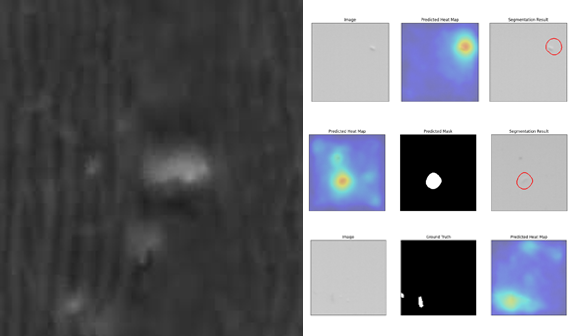

Many industries, such as electronics, plastics, jewelry face the challenge of detecting minuscule defects that often require microscopic inspection. Intelgic automates this process, eliminating the need for manual microscopic inspection.

We provide the right camera and illumination setup, which can be easily integrated into your production or inspection lines. Our team will develop the necessary algorithms, train the AI, and deliver our Live Vision software to seamlessly connect the camera system, automating the entire microscopic defect detection process.

With Intelgic, you receive a comprehensive solution for quality inspection automation, specifically tailored for microscopic defect detection.

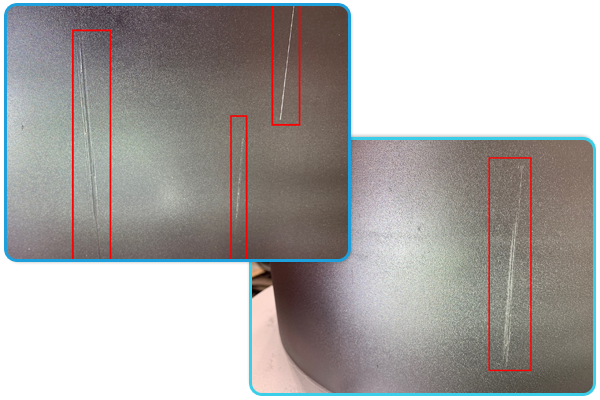

Surface defect detection automation using machine vision cameras and Live Vision software revolutionizes the quality control process in manufacturing. By combining high-resolution cameras with AI-powered algorithms, this system automatically identifies and analyzes surface defects, such as scratches, splits, dents, pits, corrosion, and discoloration, hairline defects on a wide range of materials including metal surface, coating surface, plastics, leather, sheets etc. The Live Vision software seamlessly integrates with the camera setup, providing real-time inspection and instant feedback, ensuring that any defects are detected and addressed promptly. This automated approach enhances accuracy, speeds up production, and reduces the risk of defective products reaching the market, ultimately improving overall product quality and efficiency.

In complex manufacturing environments or when inspecting large parts, multiple cameras may be required to ensure comprehensive coverage and accurate defect detection. Each camera in the setup can be customized with specific specifications based on factors like working distance, defect size, and product dimensions. Intelgic offers complete, tailored defect detection automation solutions for a wide range of industries, including car parts manufacturing. Our approach includes designing and implementing customized quality assurance inspection systems that seamlessly integrate multiple cameras, ensuring every aspect of the product is thoroughly inspected. This personalized solution enhances inspection accuracy, efficiency, and overall product quality in your manufacturing process.

©2025 Intelgic Inc. All Rights Reserved.